How to choose a gas sealing solution?

To select the best sealing material for a gas system its constituent factors must be considered, such as the type of gas, necessary compressibility, required sealing load or seal thickness.

Sealing solutions for electrolysers

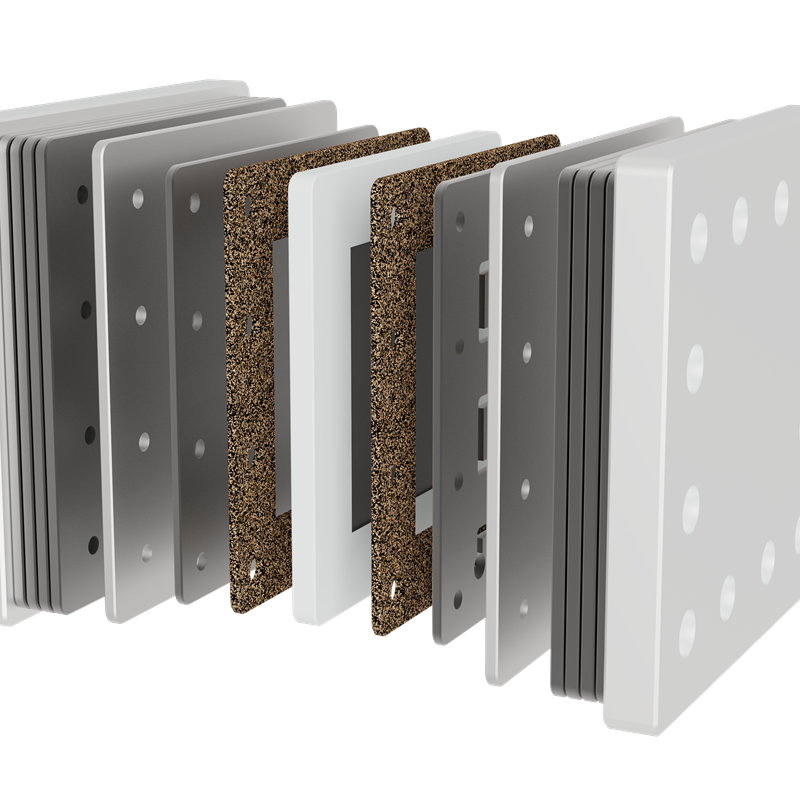

Electrolysers must be effectively and safely sealed in order to optimise their performance and maintain the electrolysis process. Electrolysis systems typically consist of several components - including membranes, electrodes and electrolytes. Sealing materials are applied to the cells where the main reactions take place, preventing electrolytes and gases from escaping. Other external components must also be sealed to ensure a safe environment around the equipment.

Amorim Tech Seal solutions, already well established in the market as effective solutions for sealing different types of gases, are now extending their applications to such hydrogen production equipment. They guarantee effective sealing through good compressibility and a low sealing load.

The Amorim Tech Seal range consists of cork composite solutions that have been specially developed for sealing different types of gases. Cork's cellular structure, which is closed and filled with air, offers advantages for such applications since it endows the system with low thermal conductivity and good acoustic performance, while minimising the material’s lateral expansion, maintaining its properties even when subjected to high levels of pressure over time.

These solutions are also extremely conformable, since they adjust to the surface and fill in possible imperfections, thereby providing a more effective and secure seal.

The fact that Amorim Tech Seal solutions incorporate cork - a 100% natural, recyclable and reusable material - guarantees increased performance while contributing to a more sustainable system, compared to using 100% rubber solutions.

Amorim Cork Composites’ DNA is based on constant innovation of its products. The company constantly strives to identify new market needs in terms of sealing materials, in function of the type of projects and specific operating conditions. This adaptation allows the company to optimise the performance and durability of its solutions and improve the overall efficiency and reliability of the systems where the solutions are used.

During a period of energy transition, strongly underpinned by a commitment to hydrogen, it is essential to choose a partner with a strong innovation policy, in order to guarantee reliable and sustainable responses to current challenges.

To select the best sealing material for a gas system its constituent factors must be considered, such as the type of gas, necessary compressibility, required sealing load or seal thickness.

Amorim Cork Composites is part of various working groups that aim to develop new industrial processes that will ensure the applicability and extensive provision of hydrogen solutions.

How Amorim Tech Seal contributes to a more efficient sealing, while improving the system’s overall sustainability?